Concrete Waterstops

Learn which type of concrete waterstop is right for your project

Concrete…it’s the universal medium. It’s used more than any other artificial material in the world. In fact, concrete’s use in modern society is exceeded only by that of naturally occurring water.

It’s the perfect medium for water retaining and water excluding structures such as dams, viaducts, swimming pools and basements.

But a concrete structure is only as watertight as the construction or expansion joints in that structure.

This is where concrete waterstops come in.

Your guide to concrete waterstops

As the name suggests, a waterstop acts to stop water. It is typically a centrally placed seal between joints within concrete to prevent water from passing through the joints.

Depending on the type of joint, different types of waterstops may need to be used such as PVC and swellable.

What is the difference between a PVC waterstop and a swellable waterstop?

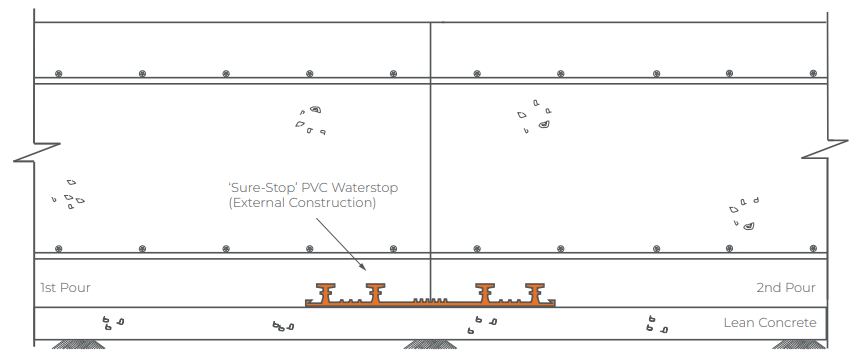

The main difference between PVC waterstops and swellable waterstops is that PVC types are generally cast 50% in to one pour and the remaining 50% is then cast into the second pour. This creates a physical barrier in the joint. The waterstop is effectively locked in both pours and water cannot pass through from either direction.

Swellable waterstops on the other hand are typically adhered on to the face of the first pour once the slab has set. The waterstop will then begin swelling when it comes in contact with the water from the second pour. It can expand by over 200%, thereby creating a pressure seal.

About PVC waterstops

There are a number of different types of PVC waterstops designed for various applications, however they are typically all joined at intersections by welding.

The ends of the joint are cut square or to the desired angle and fitted into a welding jig specific to the type of waterstop being welded. The ends are then heated to melting point using a welding iron. Once the ends are molten, they are brought together to fuse to form a continuous waterstop.

Hydrostop

Hydrostop is used as a waterstop between two new concrete structures. The two main types of Hydrostop are centrally placed and externally placed. In short, the centrally placed, or centre stop, is placed in the centre of the pour.

Typically speaking, the width of the waterstop is determined by the thickness of the concrete. I.e. a 250mm thick slab requires a 250mm waterstop. However, this will usually be specified by an engineer.

The externally placed waterstop, or rearguard waterstop, is placed at the back of the join between the two pours. This is typically adhered to formwork.

Of these two types of waterstop, there is a further two common variations – waterstops for an expansion joint or construction joint. The expansion joint waterstop features a “centre bulb” which allows for expansion and contraction of the joint where as the construction joint has no bulb.

Rearguard waterstop for expansion joint with centre bulb

Rearguard waterstop for construction join

There are numerous other specialised waterstops such as:

- TX waterstop – where a PVC waterstop is required between existing and new concrete.

- XB waterstop – is a smaller PVC profile and is used where traditional waterstops conflict with reinforcing.

- Copper waterstops – are predominately used in water retaining structures such as dams, hydro plants or water treatment facilities where they are subject to very high hydrostatic heads of water pressure against the join.

- SureShield (TPER) – a chemical resistant “cast in place” PVC waterstop for joints subject to high chemical exposure

For more information regarding these specialised waterstops, or to find out what waterstop is suitable for your project, contact our friendly team at Allcon by clicking here.

About swellable waterstops

Like PVC waterstops, there are several different types of swellable waterstops for various applications and are typically manufactured from bentonite clay or a rubber compound. Whilst each type differs in some regard, there are some crucial things to consider when selecting one for your project.

Wet/Dry Cycling: As we know, swellable waterstops expand to create a compression seal when exposed to water. If there is no more water or moisture present, the waterstop will typically shrink in size, some slightly, some back to their original size. When water or moisture appears, the joint swells again, creating the seal.

However, lower cost waterstops can deteriorate as the joint cycles from wet to dry which can result in a partial or complete failure of the joint.

Minimum Concrete Cover: This refers to the minimum distance (cover) required between the waterstop and the concrete face. Due to the expansive nature of swellable waterstops, if the waterstop is too close to the face of the concrete, the pressure created could blow the face of the concrete out, compromising the joint. If this were to happen, it is extremely difficult to rectify.

While some waterstops may seem cost effective, they require a large, sometimes impractical minimum cover. When used incorrectly, it can lead to a joint failure and a very expensive repair job.

Expansion Delay Coating: Some waterstops incorporate an expansion delay coating that prevents the joint from absorbing water from the concrete or from inclement weather before the second pour is placed. This is especially useful if the waterstop needs to be placed in advance and may be left exposed to the elements before pouring.

If the waterstop doesn’t have an expansion delay coating and the joint gets rained on prior to pouring, the joint could pre-expand, significantly reducing its effectiveness.

Head Pressure: This refers to the head pressure the waterstop can resist when properly installed. Head pressure is the pressure created from the height of the water above the joint. The greater the height and volume, the greater the pressure.

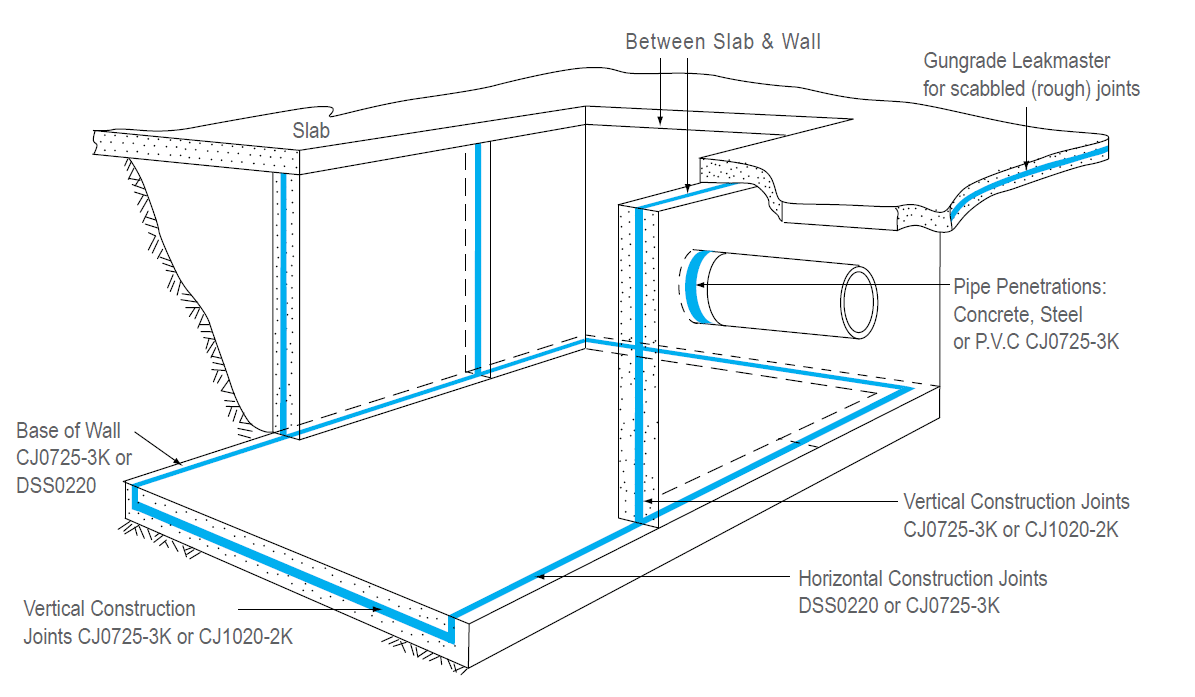

Whilst not crucial in some applications it is an important consideration when specifying waterstops. Swellable waterstops are typically used to seal horizontal and vertical construction joints to poured in-situ concrete.

Hydrotite swellable waterstop

Hydrotite is the most popular swellable waterstop and has a track record world-wide as a high quality, cost-effective solution. It consists of a unique combination of expanding hydrophilic materials and non-expanding chloroprene rubber co-extruded together to form a single strip. The co-extrusion means that the expansion is directed across the join creating an extremely effective compression seal within the joint, shutting out water ingress.

Hydrotite is available in 2mm, 7mm and 10mm thicknesses and all feature an adhesive strip backing to enable adhering directly to the concrete surface. The thickness should be verified and approve by the consulting engineer on any project, however below is a general guide for the use of Hydrotite in various construction joints:

- 2mm – pipe penetrations, horizontal construction joints

- 7mm – pipe penetrations, horizontal and vertical construction joints

- 10mm – horizontal and vertical construction joints

There are other profiles of Hydrotite available for leak repairs and z-bar holes etc.

Finally, Hydrotite is not affected by wet/dry cycling, has an expansion delay coating, has a minimum cover of 50mm and is capable of sealing a 30m head of water.

Leakmaster swellable waterstop

Leakmaster is a one component polyurethane hydrophilic gun grade waterstop. Available in a 320ml cartridge, Leakmaster is used to provide a swellable seal on rough, scabbled surfaces and around pipe penetrations. Once hardened, Leakmaster can swell up to 2 times by volume sealing up to a 20m head of water.

Superswell 47B swellable waterstop

Like other hydrophilic waterstops, Superswell 47B expands when exposed to moisture to form a compression seal in concrete joints. Where it differs from other seals is its ability to expand to create a self-healing joint. It also complies to NSF/ANSI Standard 60 Drinking Water System Components – Health Effects, ensuring its safe for use in drinking water applications such as water tanks, swimming pools and reservoirs.

The other unique feature of Superswell 47B will not expand to the point that it begins disintegrating.

Superswell 47B is not affected by wet/dry cycling, has an expansion delay coating, has a minimum cover of 50mm and is capable of sealing a 60m head of water. It also features an adhesive backing to enable application directly to clean and smooth concrete surfaces.

Volclay RX swellable waterstop

Bentonite is widely used in many industries, from farming to medical, manufacturing and purification thanks to its super absorbent properties. Volclay RX is a sodium bentonite based waterstop which expands up to 3 times its volume when it comes into contact with water to seal and fill voids and joins in concrete.

Volclay waterstop RX is available in the following 3 different sizes and shapes:

- RX101 – a rectangular shape strip 25mm x 19mm and is used for joints over 200mm thick and has a minimum cover of 75mm

- RX101T – similar to the RX101, however it has a trapezoidal shape which allows for even more distribution of pressure and allows the concrete to flow more readily over the product during placement. It can be used in joints over 200mm thick or a cover of 75mm.

- RX102 – a smaller domed shaped strip for use in walls greater than 125mm thick and in horizontal concrete 100mm thick or greater. RX102 requires a minimum cover of 50mm.

Volclay RX has been independently tested to resist a hydrostatic head pressure of 70m. It has also been independently tested to 25 wet/dry cycles with no adverse effects. However, it is not a self-adhering product. It must be secured using Cetseal, a multi-purpose moisture cure sealant. Mechanical fasteners can also be used in conjunction with the Cetseal to hold the product in place while the adhesive cures. Finally, it does not claim to have any expansion delay capabilities.

Quick overview of swellable waterstops:

Product | Wet/Dry Cycling | Expansion Delay | Minimum Cover | Hydrostatic Head Pressure | Suitable for Drinking Water |

Hydrotite | Yes | Yes | 50mm | 30m | Not approved |

Leakmaster | Yes | No | 50mm | 20m | Not approved |

Superswell 47B | Yes | Yes | 50mm | 60m | Approved |

Volclay RX101 & 101T | Yes | No | 75mm | 70m | Not approved |

Volclay RX102 | Yes | No | 50mm | 70m | Not approved |

Not sure which type of concrete waterstop is right for your project? Talk to the Allcon team

With foundations stretching back over 30 years, we understand the concrete construction industry.

We’re here to help make your job easier. You can always rely on our experienced team of specialists to offer detailed product knowledge on everything from waterstops to equipment and everything in between.

Contact Us

We can solve your problem.

Put us to the test today.